HAIMER - WINTOOL TOOL MANAGEMENT SOFTWARE| JSR GROUP

WINTOOL

TOOL MANAGEMENT SOFTWARE

THE ALL ENCOMPASSING PRODUCTION SOFTWARE

|

HAIMER: WORLDWIDE DISTRIBUTION PARTNER The Haimer Group is now a global competence partner and offers its worldwide customers WinTool and Toolbase products as a full-service provider. |

|

WINTOOL – THE LEADING PROVIDER FOR TOOL & DATA MANAGEMENT With WinTool you simplify your manufacturing processes, reduce production costs and increase productivity. You benefit from shorter programming and setup times, reduce the stock as well as the tool variety and work with organized and integrated manufacturing documentation. |

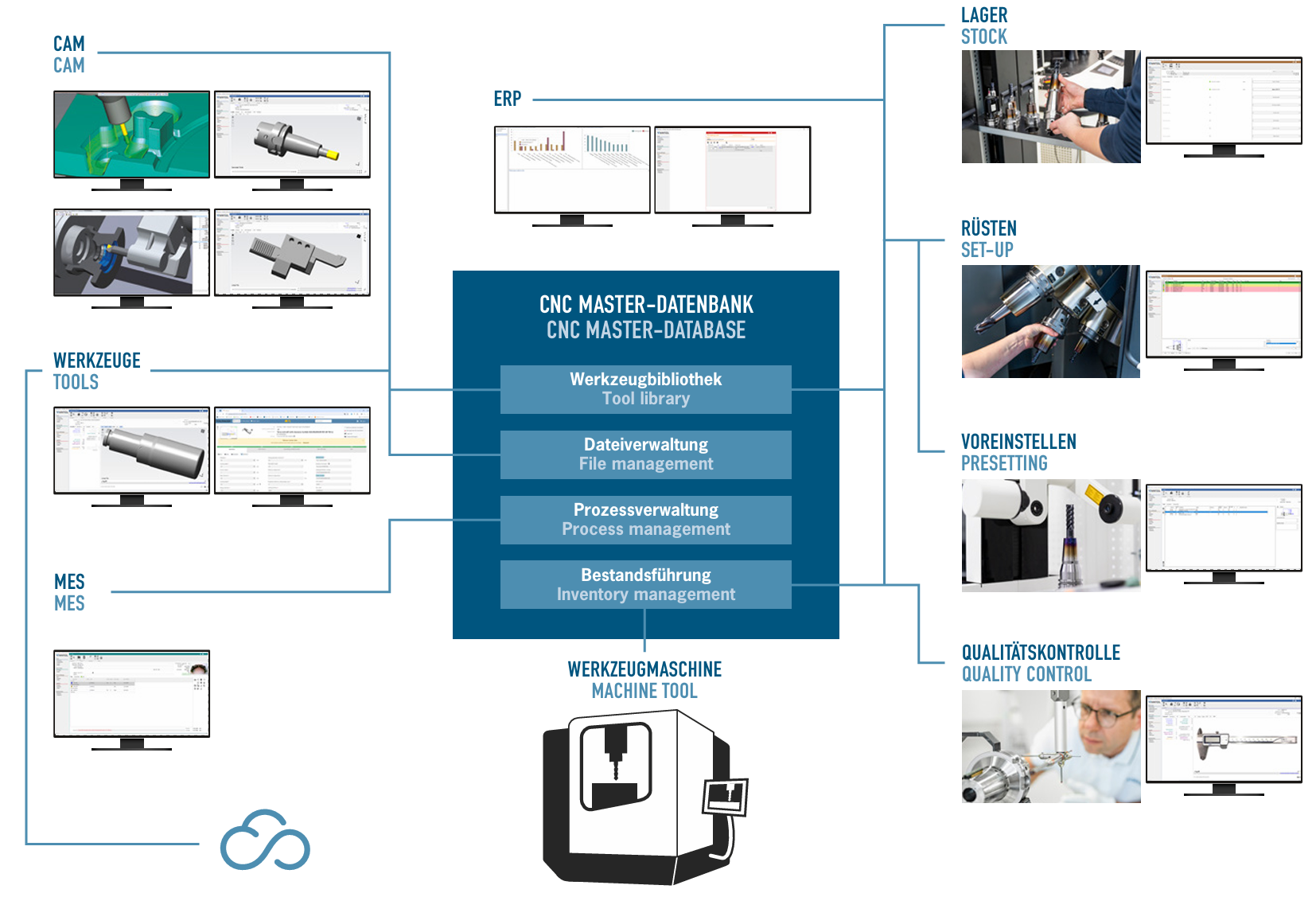

Machining Data Management with WinTool Are you familiar with the term “Machining Data Management”? WinTool is CNC file and tool management, Industry 4.0 and Lean Management in one package. WinTool is the process-oriented tool management, so that you use your machines, manpower and resources efficiently in order to become a leading industrial machining company! |

WinTool is the only independent solution provider for tool management and cooperates with all manufacturers of tools, measuring devices, CAM systems etc. This way you maintain your independence and flexibility towards your suppliers.

Organizing a lean and flexible workflow increases your company‘s productivity and minimizes setup times and operating costs. So what could be better than an ingenious and easy-to-use tool and data management system that enables you to achieve exactly these goals? With WinTool, you have found the right solution since WinTool AG is a specialized swiss company that has been developing and supporting software solutions for the efficient organization of CNC manufacturing since 1980.

YOUR BENEFITS

|

1.TOOL & RESOURCE LIBRARY The key to efficiency Benefits Efficient resource planning, CAM programming, and machine scheduling with huge time savings Features Comprehensive, truly parametric tool library with a graphics generator and fast tool manufacturer data input.

3.CNC PROCESS MANAGEMENT CNC data management for Production orders Benefits Minimum setup times mean maximum machining capabilities Features Loading and unloading lists of tool assemblies for machines |

2.CNC FILE MANAGEMENT Standardize your machine setup processes as well as your data management processes Benefits Standardized production documents in digital production folders Features Archiving via drag & drop or automatically

4.INVENTORY MANAGEMENT Links NC programs, tool lists and tool availability for total transparency! Benefits Security of supply Features Minimum inventory control and ERP interface |